Home ProductsStone MachineryStone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

SMART-CUT 800 OPTIMA 5 axis CNC bridge saw with vacuum lift

FOB Price:

Type:

Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Usage:

Granite, Marble, Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

You may also like

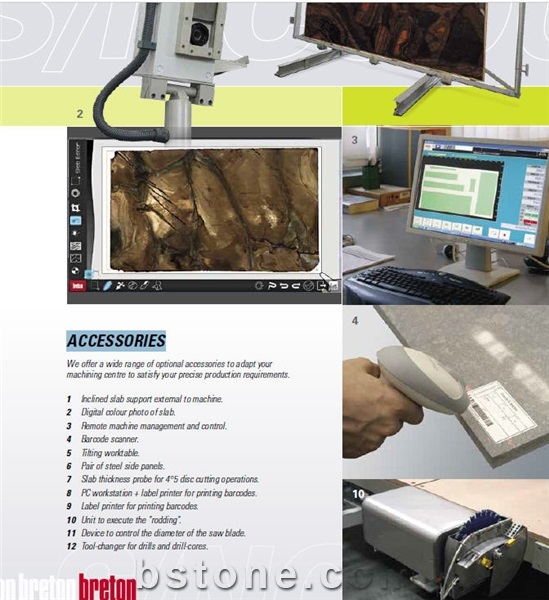

Machinery Function Features

SMART-CUT 800 OPTIMA 5 axis CNC bridge saw with built-in vacuum lifting

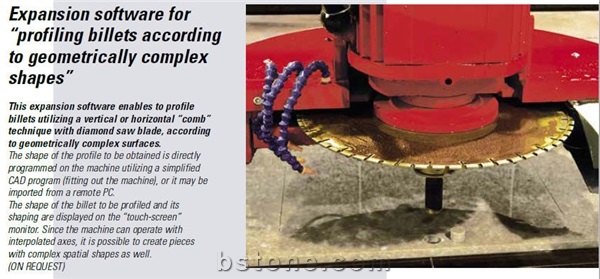

Expansion software for profiling billets according to geometrically complex shapes

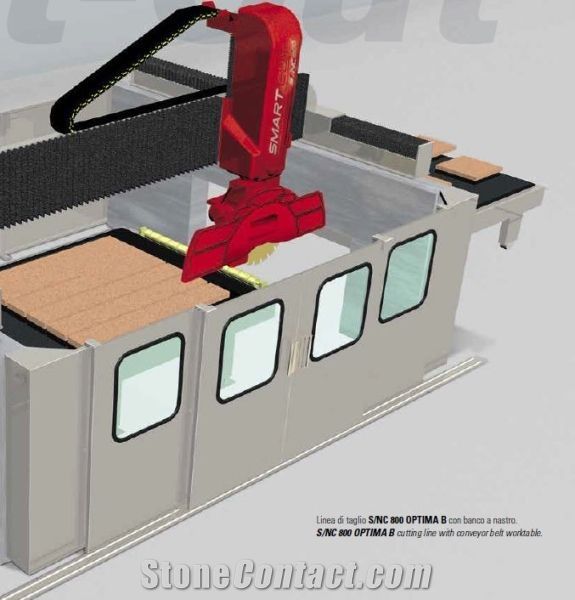

SMART-CUT 800 OPTIMA Bridge saw for marble, granite, sandstone, limestone, and stone for the production of worktops with vacuum cup pick and place system

BRIDGE SAW WITH A PICK-UP UNIT WITH SUCTION CUPS

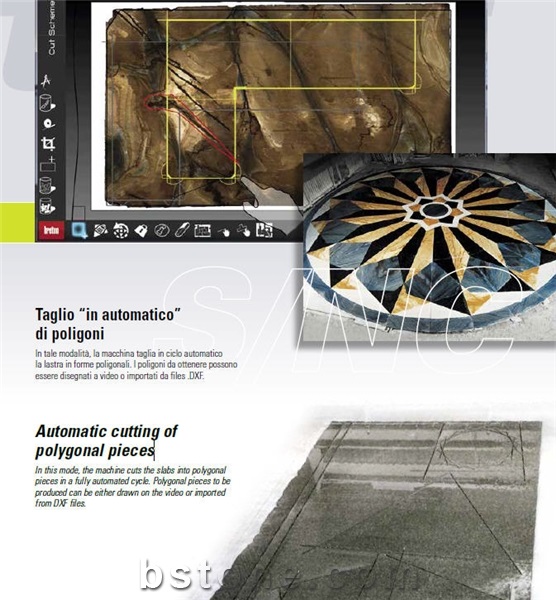

Smart-Cut 800 Optima is a numerical control bridge saw cutting centre with interpolated axes, rotating head, specially engineered to cut in either the plunge-cut or step-cut mode, and shape, items of granite, marble, sandstone, limestone, engineered stone and suchlike.

The machine is equipped with a pick-up unit with suction cups used to lift and space out the pieces for cut optimization, and move the pieces in order to work out the engravings for the rods.

Available accessories are a belt table and an automatic shuttle to unload the semifinished pieces and off-cuts and take them outside the working area.

STRUCTURAL AND FUNCTIONAL FEATURES

- Latest generation SIEMENS 840 SL digital NC.

- High-speed and high-precision movements along axes X, Y, Z thanks to brushless digital motors with absolute encoder.

- Spindle carriage made of cast-iron to ensure rigidity and vibration damping.

- The beam is moved by a precision rack and pinion assembly, driven by brushless digital motor.

- The spindle carriage is moved by recirculating roller runner blocks, driven by brushless digital motor that ensures the required precision and rigidity.

- The spindle is moved vertically by a ball screw/preloaded nut assembly on recirculating roller guides, driven by digital brushless motor.

- All guides are protected and greased.

- Twist head with a ± 190° rotation on axis “C” and 0° to 90° rotation on axis “A”.

- The disc inclination is motorized and can be programmed in any position between 0° and 90°, with possibility of making step-cutting (with continuous head rotation).

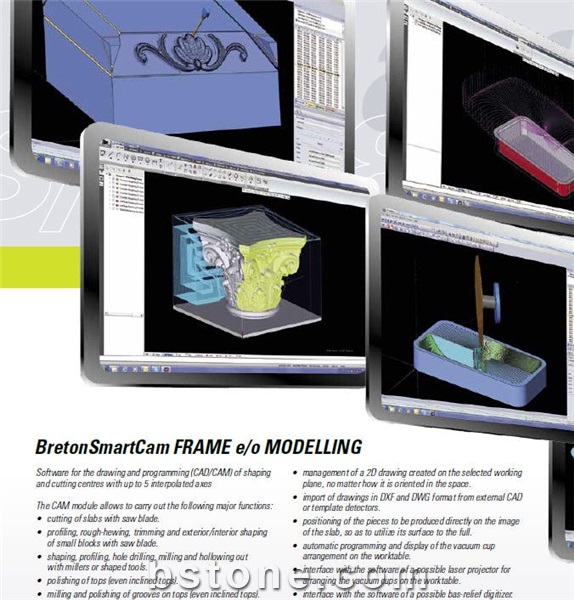

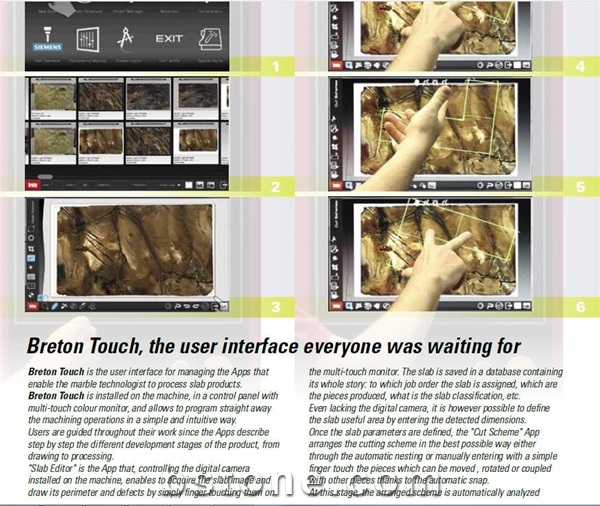

- User-friendly software displayed on colour touch-screen, which is mounted on the control panel; joysticks for moving the various working axes easily.

- Laser tracer displaying the cutting path.

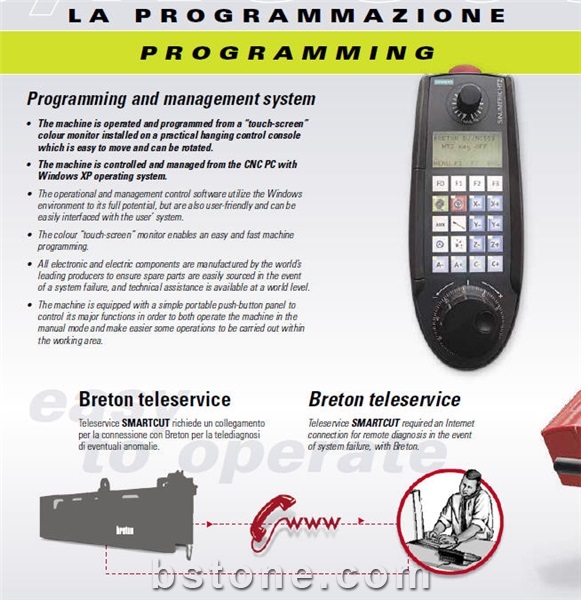

PROGRAMMING AND MANAGEMENT SYSTEM

- The machine is managed and programmed from a colour touch-screen installed on a practical, hanging control console, which is easy to handle and can be rotated.

- The machine is controlled from the CNC PC with Windows operating system.

- The management and operational software use the Windows environment to its full potential, are extremely user-friendly and can be easily interfaced with the user’s system.

- The colour touch-screen makes the machine programming easy and fast.

- All electric and electronic components are from world’s leading producers so as to ensure that spare parts can be easily sourced in the event of a system failure, and technical assistance is available at a world level.

- The machine is equipped with a simple portable button panel to control its major functions in order to operate it in the manual mode and make easier some operations to be carried out within the working area.

BRETON TELESERVICE

SMART-CUT is to be networked for connection with Breton, for the remote diagnosis of any possible malfunction.

Expansion software for profiling billets according to geometrically complex shapes

SMART-CUT 800 OPTIMA Bridge saw for marble, granite, sandstone, limestone, and stone for the production of worktops with vacuum cup pick and place system

BRIDGE SAW WITH A PICK-UP UNIT WITH SUCTION CUPS

Smart-Cut 800 Optima is a numerical control bridge saw cutting centre with interpolated axes, rotating head, specially engineered to cut in either the plunge-cut or step-cut mode, and shape, items of granite, marble, sandstone, limestone, engineered stone and suchlike.

The machine is equipped with a pick-up unit with suction cups used to lift and space out the pieces for cut optimization, and move the pieces in order to work out the engravings for the rods.

Available accessories are a belt table and an automatic shuttle to unload the semifinished pieces and off-cuts and take them outside the working area.

STRUCTURAL AND FUNCTIONAL FEATURES

- Latest generation SIEMENS 840 SL digital NC.

- High-speed and high-precision movements along axes X, Y, Z thanks to brushless digital motors with absolute encoder.

- Spindle carriage made of cast-iron to ensure rigidity and vibration damping.

- The beam is moved by a precision rack and pinion assembly, driven by brushless digital motor.

- The spindle carriage is moved by recirculating roller runner blocks, driven by brushless digital motor that ensures the required precision and rigidity.

- The spindle is moved vertically by a ball screw/preloaded nut assembly on recirculating roller guides, driven by digital brushless motor.

- All guides are protected and greased.

- Twist head with a ± 190° rotation on axis “C” and 0° to 90° rotation on axis “A”.

- The disc inclination is motorized and can be programmed in any position between 0° and 90°, with possibility of making step-cutting (with continuous head rotation).

- User-friendly software displayed on colour touch-screen, which is mounted on the control panel; joysticks for moving the various working axes easily.

- Laser tracer displaying the cutting path.

PROGRAMMING AND MANAGEMENT SYSTEM

- The machine is managed and programmed from a colour touch-screen installed on a practical, hanging control console, which is easy to handle and can be rotated.

- The machine is controlled from the CNC PC with Windows operating system.

- The management and operational software use the Windows environment to its full potential, are extremely user-friendly and can be easily interfaced with the user’s system.

- The colour touch-screen makes the machine programming easy and fast.

- All electric and electronic components are from world’s leading producers so as to ensure that spare parts can be easily sourced in the event of a system failure, and technical assistance is available at a world level.

- The machine is equipped with a simple portable button panel to control its major functions in order to operate it in the manual mode and make easier some operations to be carried out within the working area.

BRETON TELESERVICE

SMART-CUT is to be networked for connection with Breton, for the remote diagnosis of any possible malfunction.

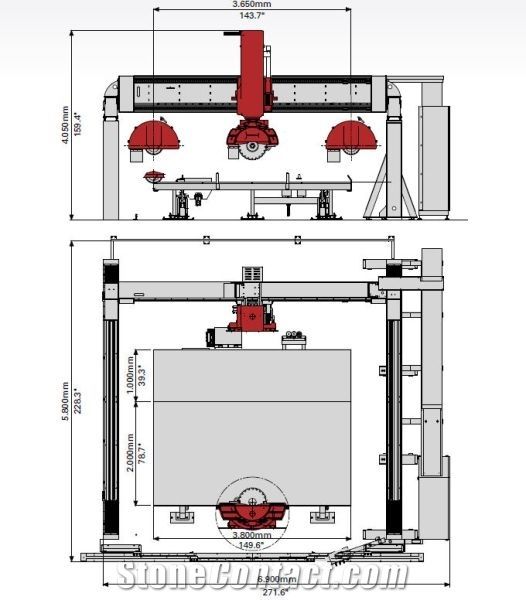

Technical Data

Parameters |

Unit |

S/NC 800 OPTIMA |

S/NC 800B OPTIMA |

Max. workable thickness(with 1200mm blade) |

mm |

240 |

240 |

Dimensions of the work table(L×W) |

mm |

3800 x 3000 |

3800 x 3000 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

0 ÷ 40 |

0 ÷ 40 |

Machine height |

mm |

4050 |

4050 |

Diameter of the blades that can be applied with “Multicup” |

mm |

350 ÷ 550 |

350 ÷ 550 |

Max. revolutions of the spindle unit |

rpm |

6000 |

6000 |

Transversal stroke speed (Y displacement speed) |

m/min |

0 ÷ 40 |

0 ÷ 40 |

Vertical stroke speed (Z displacement speed) |

m/min |

0 ÷ 10 |

0 ÷ 10 |

Disc diameter |

mm |

350 ÷ 1000 |

350 ÷ 1000 |

Max. workable thickness(with 600mm blade) |

mm |

160 |

160 |

Machine width |

mm |

6900 |

6900 |

Head motor power |

kW |

26.5 |

26.5 |

Bridge transversal stroke(Y axis travel) |

mm |

3800 |

3800 |

C axis blade rotation |

° |

380° |

380° |

Horizontal stroke(X axis travel) |

mm |

3650 |

3650 |

Machine length |

mm |

5800 |

5800 |

Average level of equivalent sound pressure |

dbA |

84 |

84 |

Approximate weight without table |

kg |

8000 |

9000 |

Tools holder head inclination(A axis blade rotation) |

° |

0° ÷ +90° |

0° ÷ +90° |

Head raising/lowering stroke(Z axis travel) |

mm |

700 |

700 |

Components

Recommended CNC Bridge Cutting Machine Products

Stefano Titotto

Stefano Titotto