Home ProductsStone MachineryStone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Breton SMART-CUT 800 5 Axis CNC Mobile Bridge Saw

FOB Price:

Type:

Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Usage:

Granite, Marble, Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

You may also like

Machinery Function Features

SMART-CUT 800 - 5 AXIS CNC BRIDGE SAW FOR SHAPING AND SAWING

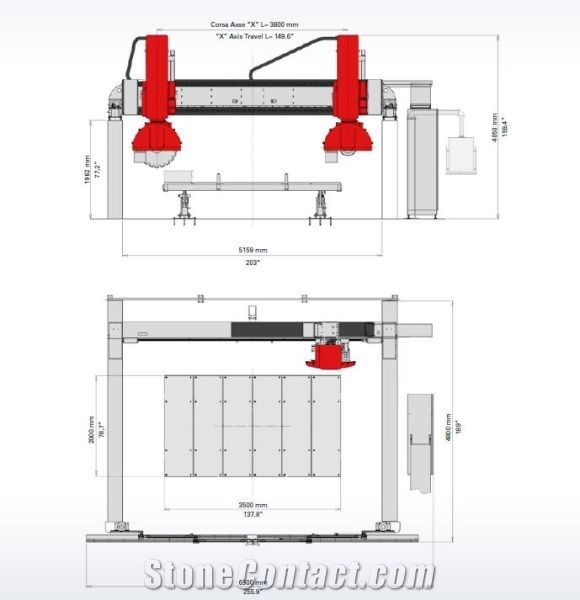

Smart-Cut 800 is a 5 axis CNC bridge saw. Its five controlled axes which can interpolate on the three Cartesian axes while the other two axes can be positioned at will; the machine cuts marble, granite, sandstone, limestone and stone slabs into machined items, shapes billets according to programmed profiles using a saw blade tool, contours profiles and performs the stock removal on billets using a shaped tool.

STRUCTURAL AND FUNCTIONAL FEATURES

• SMART-CUT S/NC800 is a NC bridge saw with 5 interpolated axes and is fitted with a revolving head and fixed worktable with tilting feature (upon specific request).

• The fixed worktable for the S/NC800 B model is fitted with a motorised conveyor belt automating loading and unloading operations.

• Latest generation SIEMENS 840 SL digital CNC

• High-speed and precision in movements along axes X, Y, Z thanks to the use of brushless digital motor technology with an absolute encoder.

• Spindle holder carriage in cast-iron ensures rigidity and vibration damping.

• The beam is moved by a precision rack and pinion system driven by a brushless digital motor.

• The spindle travels on recirculating roller skids driven by a brushless digital motor ensuring precision and rigidity.

• The spindle travels on guides fitted with a recirculating roller assembly driven by a ball screw assembly with a preloaded ball nut.

• All guides are protected and greased.

• Twist head with a ± 190° rotation on axis “C” and 0° to 90° rotation on axis “A”.

• Tilting cutting disc which is motorised and can be programmed in any position between 0° to 90° offering the possibility of step cutting (with continuous head rotation).

• User friendly software and touch-screen colour monitor mounted to a control panel, joystick controls for moving the various axes.

• Laser tracer for displaying cutting path

Smart-Cut 800 is a 5 axis CNC bridge saw. Its five controlled axes which can interpolate on the three Cartesian axes while the other two axes can be positioned at will; the machine cuts marble, granite, sandstone, limestone and stone slabs into machined items, shapes billets according to programmed profiles using a saw blade tool, contours profiles and performs the stock removal on billets using a shaped tool.

STRUCTURAL AND FUNCTIONAL FEATURES

• SMART-CUT S/NC800 is a NC bridge saw with 5 interpolated axes and is fitted with a revolving head and fixed worktable with tilting feature (upon specific request).

• The fixed worktable for the S/NC800 B model is fitted with a motorised conveyor belt automating loading and unloading operations.

• Latest generation SIEMENS 840 SL digital CNC

• High-speed and precision in movements along axes X, Y, Z thanks to the use of brushless digital motor technology with an absolute encoder.

• Spindle holder carriage in cast-iron ensures rigidity and vibration damping.

• The beam is moved by a precision rack and pinion system driven by a brushless digital motor.

• The spindle travels on recirculating roller skids driven by a brushless digital motor ensuring precision and rigidity.

• The spindle travels on guides fitted with a recirculating roller assembly driven by a ball screw assembly with a preloaded ball nut.

• All guides are protected and greased.

• Twist head with a ± 190° rotation on axis “C” and 0° to 90° rotation on axis “A”.

• Tilting cutting disc which is motorised and can be programmed in any position between 0° to 90° offering the possibility of step cutting (with continuous head rotation).

• User friendly software and touch-screen colour monitor mounted to a control panel, joystick controls for moving the various axes.

• Laser tracer for displaying cutting path

Technical Data

Parameters |

Unit |

S/NC 800 |

S/NC 800 B |

Max. revolutions of the spindle unit |

rpm |

6000 |

6000 |

Machine height |

mm |

4050 |

4050 |

Max. workable thickness(with 1200mm blade) |

mm |

240 |

240 |

Bridge transversal stroke(Y axis travel) |

mm |

2800 |

2800 |

Transversal stroke speed (Y displacement speed) |

m/min |

0 ÷ 40 |

0 ÷ 40 |

Approximate weight without table |

kg |

7000 |

7000 |

Machine width |

mm |

6500 |

6500 |

Machine length |

mm |

4800 |

4800 |

Vertical stroke speed (Z displacement speed) |

m/min |

0 ÷ 10 |

0 ÷ 10 |

Dimensions of the work table(L×W) |

mm |

3800x2200 |

3800x2200 |

Head motor power |

kW |

26.5 |

26.5 |

Tools holder head inclination(A axis blade rotation) |

° |

0° ÷ +90° |

0° ÷ +90° |

Average level of equivalent sound pressure |

dbA |

80 |

80 |

Disc diameter |

mm |

400 ÷ 800 |

400 ÷ 800 |

C axis blade rotation |

° |

±190° |

±190° |

Head raising/lowering stroke(Z axis travel) |

mm |

700 |

700 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

0 ÷ 40 |

0 ÷ 40 |

Horizontal stroke(X axis travel) |

mm |

3800 |

3800 |

Recommended CNC Bridge Cutting Machine Products

Stefano Titotto

Stefano Titotto