LAMGEA Moldless Ceramic Pressing System For Large Formats

FOB Price:

Type:

Artificial Stone MachinesPressing Machine

Usage:

Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Machinery Function Features

The moldless ceramic pressing system for large formats

Lamgea is the ceramic moldless press for the production of ceramic slabs and large format ceramic tiles. Lamgea works with classic standard atomized materials, from stoneware to red body, monoporous, dry-ground and so on, with a consequent reduction in industrial costs.

HIGH FLEXIBILITY AND QUALITY STANDARDS

The leading ceramic pressing technology for the production of large-format ceramic slabs up to 1800 x 4800 mm with variable thicknesses from 3 to 30 mm, making it possible to obtain structured surfaces of up to 2 mm of depth.

Lamgea guarantees an increase in productivity while maintaining high quality:

production up to 17.000 sq.m/day

maximum flexibility in changes of format and in variations in thickness and without any belt change

CERAMIC SURFACES WITH NO PLANARITY DEFECTS

The atomized powders are laid on the belt with dispensers linked to a doctoring system. In the event of variations in humidity or granulometry in the extended layer of powder, the retroactive control system makes it possible to correct the thickness with the squeegee and automatically adjust it in the following cycle.

Thanks to the even laying and to a pressing which is progressive, with still atomized material, Lamgea guarantees:

improved uniformity on the entire surface with planarity up to 0.1 mm

improved geometry of the fired tile with a caliber per side less than or equal to 2 mm

THE ADVANTAGES OF LAMGEA TECHNOLOGY

During the pressing phase without any mold the atomized materiali can expand without generating any residual stresses. This enables to produce big slabs thinner and lighter weight per sq.m having the following benefits:

lower consumption of raw materials and energy

lower consumption of tools for rectification and lapping

less waste during the rectification phase

Consequently, strong advantages in terms of costs are generated.

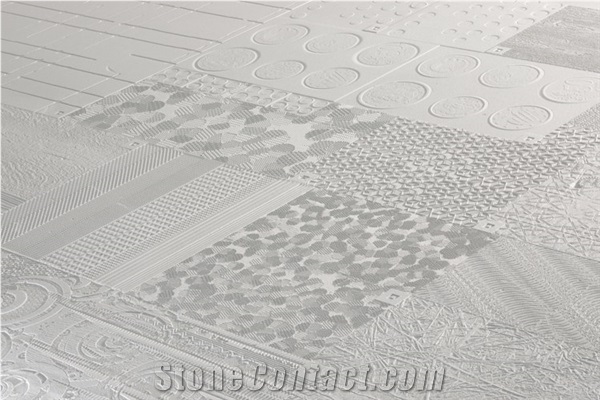

CERAMIC SLABS WITH THREE-DIMENSIONAL DESIGN

With Lamgea it’s possible to recreate any type of structured surface and three-dimensional effect thanks to the possibility of engraving the upper belt with a laser, starting from a graphic file.

16.6 linear meters of extension

Deep incision up to 3 mm

High resolution

Maximum geometric regularity (the pattern does not alter)

Lamgea is the ceramic moldless press for the production of ceramic slabs and large format ceramic tiles. Lamgea works with classic standard atomized materials, from stoneware to red body, monoporous, dry-ground and so on, with a consequent reduction in industrial costs.

HIGH FLEXIBILITY AND QUALITY STANDARDS

The leading ceramic pressing technology for the production of large-format ceramic slabs up to 1800 x 4800 mm with variable thicknesses from 3 to 30 mm, making it possible to obtain structured surfaces of up to 2 mm of depth.

Lamgea guarantees an increase in productivity while maintaining high quality:

production up to 17.000 sq.m/day

maximum flexibility in changes of format and in variations in thickness and without any belt change

CERAMIC SURFACES WITH NO PLANARITY DEFECTS

The atomized powders are laid on the belt with dispensers linked to a doctoring system. In the event of variations in humidity or granulometry in the extended layer of powder, the retroactive control system makes it possible to correct the thickness with the squeegee and automatically adjust it in the following cycle.

Thanks to the even laying and to a pressing which is progressive, with still atomized material, Lamgea guarantees:

improved uniformity on the entire surface with planarity up to 0.1 mm

improved geometry of the fired tile with a caliber per side less than or equal to 2 mm

THE ADVANTAGES OF LAMGEA TECHNOLOGY

During the pressing phase without any mold the atomized materiali can expand without generating any residual stresses. This enables to produce big slabs thinner and lighter weight per sq.m having the following benefits:

lower consumption of raw materials and energy

lower consumption of tools for rectification and lapping

less waste during the rectification phase

Consequently, strong advantages in terms of costs are generated.

CERAMIC SLABS WITH THREE-DIMENSIONAL DESIGN

With Lamgea it’s possible to recreate any type of structured surface and three-dimensional effect thanks to the possibility of engraving the upper belt with a laser, starting from a graphic file.

16.6 linear meters of extension

Deep incision up to 3 mm

High resolution

Maximum geometric regularity (the pattern does not alter)

Recommended Pressing Machine Products

Buyers' Request

Esm***Wrote:

Esm***Wrote:

Hi Please send me the lamgea press catalog.

Gianluca Poli

Gianluca Poli