Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Complete Line For Curbstone Cutting And Chamfering

FOB Price:$50000-80000

Type:

Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

30days

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Port:

Xiamen Port- China

Delivery Details: FOB,CFR,CIF,EXW

Payment :

More

You may also like

Machinery Function Features

kerbstone Slicing Machine Line DFLSX1200-13S

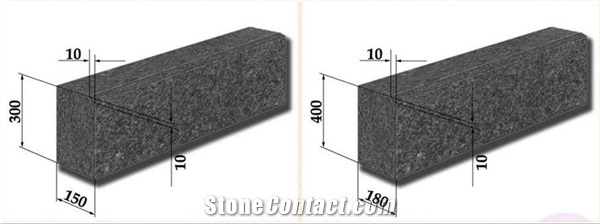

This machine line is mainly for cutting slab width above 50mm, the machine cut with 10-14pcs of blade at the same time which will dramatically increase cutting speed and overal output, daily capacity can reach 30-35m³/24h.The machine is widely used for kerbstone, roadside stone, cobblestone and tombstone etc.

Machine part:

The machine line included one slicing machine(DF1200-12S) and one edge cutting machine(DF1200-1S), worker load thick slab to the slicing machine with a crane, after slicing machine finish cutting, the roller on worktable hydraulically lift up and transfer the stone to the next edge cutting machine.

The edge cutting machine has hydraulic pushers to push all the stone with blade gap tight and together to ensure a precise cutting. After that, the cutting process is finished and ready for packaging.

electrical part:

Machine use Mitsubishi PLC control system, SIEMENS water proof button, Omron relays etc, the machine is equipped with remote control, worker can both use the controlling cabin or remote control during operation.

Advantage:

1.Segments saving: machine use multi-blade cut at the same time, every down cut is about 3-5mm(depends on stone and segment), which save segments consuming.

2.Labor saving: the entire machine line only need one worker to attend to it, machine adopts rollers to transfer stone and sensors for automatic stop and operation.

3.Workshop space saving: compared to other cutting methods, the machine need only 12*5m space when producing same capacity.

Features:

1. no cement foundation needed, easy installation and shipment(40’’ HQ).

2. the main shaft adopts high frequency modulation treatment, which will be more durable and wear-resisting.

3. machine uses main spindle and a vice spindle to seal all saw blades together which can ensure the machine stable while cutting hard granite.

4. it uses a simple program of movement on the controlling box, easy for setting, operating, and maintaining.

5. it adopts two hydraulic pillars(a set of hydraulic systems) on both sides of the machine to ensure the strength of cutting spindle lifting up and down.

6. Unlike traditional stone cutting, it dramatically increases productivity and reduces labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.

7. Cast iron is adopted in the main frame of the machine to make the machine more stable with less chance of vibration under the operating condition.

8.The regular worktable length of the shaft is 1.6m(1.8m optional)

The slicing machine use a main spindle and a vice spindle sealing together which can ensure the machine stable while cutting hard granite.

Protectors for motor and wires to prevent from dust and water

Cast-iron

The spindle adopts High frequency modulation treatment, which will be more durable and wear-resisting

Galvanized protector to the chain and gear for safty handling

Complete Machine Line (1 Edge Cutting Machine + 1 Slicing Machine)

Slicing Machine DF1200-12S Edge Cutting Machine DF1200-1S

Dimension 5500×2300×2500mm Dimension 5500×4000×4500mm

Diameter of blade 1200mm Diameter of blade 1200mm

Number of blades 12pcs Number of blades 1pcs

Max.cutting size 2500×1800×450mm Worktable size 2500×1800mm

Worktable size 2500×1800mm Working length max 2500mm

Weight 10t Max.vertical stroke 600mm

Max.cutting depth 450mm Weight 9t

Main motor power 55kw-6 Max.cutting depth 450mm

Max.vertical stroke 600mm Main motor power 22kw-6

It produces about 30-35m³ of stone every day (24h) and covers a total space of 12m*5m.

Project showcase:

★ chamfering machine for stone cutting machine line DF400

( With stone loading and turnover system )

The chamfering machine can be combined with above-cutting machine as a whole line for kerbstone cutting machine cutting, only 4 workers needed from loading to packaging the finished products.

Technical Data

Dimension (mm) 6000*1650*1600

diameter of blade (mm) 300

Chamfering range (mm) 100-500

Motor(kw) 11+11

Complete line showcase:

Space for entire line:24*5m

This machine line is mainly for cutting slab width above 50mm, the machine cut with 10-14pcs of blade at the same time which will dramatically increase cutting speed and overal output, daily capacity can reach 30-35m³/24h.The machine is widely used for kerbstone, roadside stone, cobblestone and tombstone etc.

Machine part:

The machine line included one slicing machine(DF1200-12S) and one edge cutting machine(DF1200-1S), worker load thick slab to the slicing machine with a crane, after slicing machine finish cutting, the roller on worktable hydraulically lift up and transfer the stone to the next edge cutting machine.

The edge cutting machine has hydraulic pushers to push all the stone with blade gap tight and together to ensure a precise cutting. After that, the cutting process is finished and ready for packaging.

electrical part:

Machine use Mitsubishi PLC control system, SIEMENS water proof button, Omron relays etc, the machine is equipped with remote control, worker can both use the controlling cabin or remote control during operation.

Advantage:

1.Segments saving: machine use multi-blade cut at the same time, every down cut is about 3-5mm(depends on stone and segment), which save segments consuming.

2.Labor saving: the entire machine line only need one worker to attend to it, machine adopts rollers to transfer stone and sensors for automatic stop and operation.

3.Workshop space saving: compared to other cutting methods, the machine need only 12*5m space when producing same capacity.

Features:

1. no cement foundation needed, easy installation and shipment(40’’ HQ).

2. the main shaft adopts high frequency modulation treatment, which will be more durable and wear-resisting.

3. machine uses main spindle and a vice spindle to seal all saw blades together which can ensure the machine stable while cutting hard granite.

4. it uses a simple program of movement on the controlling box, easy for setting, operating, and maintaining.

5. it adopts two hydraulic pillars(a set of hydraulic systems) on both sides of the machine to ensure the strength of cutting spindle lifting up and down.

6. Unlike traditional stone cutting, it dramatically increases productivity and reduces labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.

7. Cast iron is adopted in the main frame of the machine to make the machine more stable with less chance of vibration under the operating condition.

8.The regular worktable length of the shaft is 1.6m(1.8m optional)

The slicing machine use a main spindle and a vice spindle sealing together which can ensure the machine stable while cutting hard granite.

Protectors for motor and wires to prevent from dust and water

Cast-iron

The spindle adopts High frequency modulation treatment, which will be more durable and wear-resisting

Galvanized protector to the chain and gear for safty handling

Complete Machine Line (1 Edge Cutting Machine + 1 Slicing Machine)

Slicing Machine DF1200-12S Edge Cutting Machine DF1200-1S

Dimension 5500×2300×2500mm Dimension 5500×4000×4500mm

Diameter of blade 1200mm Diameter of blade 1200mm

Number of blades 12pcs Number of blades 1pcs

Max.cutting size 2500×1800×450mm Worktable size 2500×1800mm

Worktable size 2500×1800mm Working length max 2500mm

Weight 10t Max.vertical stroke 600mm

Max.cutting depth 450mm Weight 9t

Main motor power 55kw-6 Max.cutting depth 450mm

Max.vertical stroke 600mm Main motor power 22kw-6

It produces about 30-35m³ of stone every day (24h) and covers a total space of 12m*5m.

Project showcase:

★ chamfering machine for stone cutting machine line DF400

( With stone loading and turnover system )

The chamfering machine can be combined with above-cutting machine as a whole line for kerbstone cutting machine cutting, only 4 workers needed from loading to packaging the finished products.

Technical Data

Dimension (mm) 6000*1650*1600

diameter of blade (mm) 300

Chamfering range (mm) 100-500

Motor(kw) 11+11

Complete line showcase:

Space for entire line:24*5m

Technical Data

Parameters |

Unit |

DFLSX1200-13S |

Maximum machine width |

4 |

5000 |

Approximate Weight |

Kg |

10000 |

Disc diameter |

4 |

1200 |

Disc motor power |

7 |

55 |

Usefull cutting height |

4 |

450 |

Maximum block width |

mm |

1800 |

Cut motor power |

7 |

55 |

Maximum block length |

mm |

2750 |

Maximum disc stroke |

4 |

600 |

Block holder trolley power motor |

7 |

2.2 |

Maximum block height |

mm |

450 |

Installed power |

kw |

55 |

Components

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Buyers' Request

Har***Wrote:

Har***Wrote:

Hello, I am looking for multi disc block cutting machine. Please send me price, details, pictures.

Related Products:

Machinery

Stone Factory Machines

Stone Block Cutting Machines

Giant Disc Bridge Saw Machine

Granite Giant Disc Bridge Saw Machine

Marble Giant Disc Bridge Saw Machine

Limestone Giant Disc Bridge Saw Machine

Onyx Giant Disc Bridge Saw Machine

Basalt Giant Disc Bridge Saw Machine

Quartzite Giant Disc Bridge Saw Machine

Sandstone Giant Disc Bridge Saw Machine

Travertine Giant Disc Bridge Saw Machine

Dafon Machines

6YR

6YR

Danny Pan

Danny Pan