Home ProductsStone MachineryStone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

SX-3 multi-spindle cutting centre

FOB Price:

Type:

Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

Usage:

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

20 days

Warranty:3 Months

Install and Guarantee:Customer pay for installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Machinery Function Features

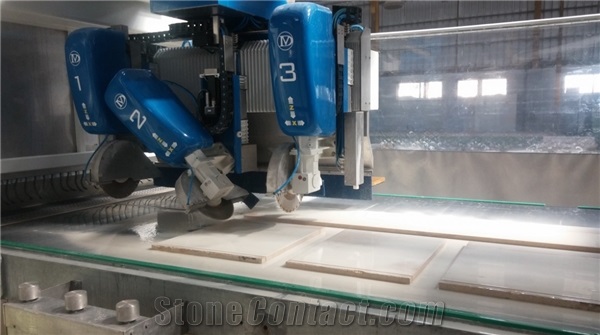

SX-3 is an innovative numerical control multi-spindle cutting centre with three cutting units with interpolated axes, designed and patented by Donatoni Macchine to satisfy those needing a compact system for large-scale production line of marble, granite and agglomerate flooring and wall coverings of various types with different sizes and thickness.

Donatoni Macchine were the first to introduce a multi-spindle machine with patented rotating bridge to the market and, rich in the experience they have built up over the years, they can guarantee their customers a very high level of productivity and at the same time complete optimisation of the slabs.

Donatoni Macchine were the first to introduce a multi-spindle machine with patented rotating bridge to the market and, rich in the experience they have built up over the years, they can guarantee their customers a very high level of productivity and at the same time complete optimisation of the slabs.

Technical Data

Parameters |

Unit |

SX-3 |

Load capacity |

Kg |

600 |

Max. number of spindle units |

nr |

6 |

Max./Min. blade diameter |

mm |

525 / 350 |

Number of interpolated axes |

nr |

12 |

Rotation of head support bridge-C Axis |

° |

-182° / +182° |

Dimensions of offloading belt |

mm |

2400 x 4000 |

Cutting belt dimensions |

mm |

2400 x 7620 |

Spindle unit motor power (marble/granite) |

kw |

17 / S6 |

Stroke-Z axis |

mm |

300 |

Machine weight |

Kg |

19500 |

Maximum depth of cutting |

mm |

150 / 65 |

Software

Parametrix is the simple and intuitive Software developed by Donatoni Macchine and designed to optimise the management of cuts of variously-shaped pieces on a slab. It enables work processes involving cuts with discs, milling cutters and drills, the insertion of straight and curved forms and shapes that have been pre-set or imported from DXF files, and the optimisation of processing times and slab surfaces.

Photoslab

It allows you to measure the surface of slabs placed on the workbench using a camera located on top of the machine and the acquisition software integrated with Parametrix.

SCAN-CNC is a measuring system consisting of a laser pointer mounted at the head of the machine and a software integrated with Parametrix that allows you to measure bi-dimensional shapes with a linear or curved form and create the drawing in real time (DXF file) on the monitor.

Recommended Multi Blade Automatic Slab Cutting Line Products

Related Products:

Machinery

Factory Machines

Stone Slab Cutting Machines

Multi Blade Automatic Slab Cutting Line

Granite Multi Blade Automatic Slab Cutting Line

Marble Multi Blade Automatic Slab Cutting Line

Limestone Multi Blade Automatic Slab Cutting Line

Slate Multi Blade Automatic Slab Cutting Line

Onyx Multi Blade Automatic Slab Cutting Line

Artificial Stone Multi Blade Automatic Slab Cutting Line

Basalt Multi Blade Automatic Slab Cutting Line

Quartzite Multi Blade Automatic Slab Cutting Line

Sandstone Multi Blade Automatic Slab Cutting Line

Travertine Multi Blade Automatic Slab Cutting Line

Donatoni Machines

Luca Donatoni

Luca Donatoni