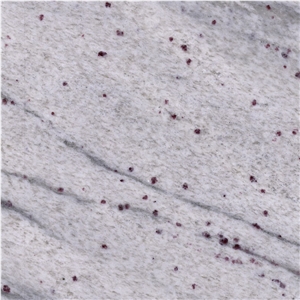

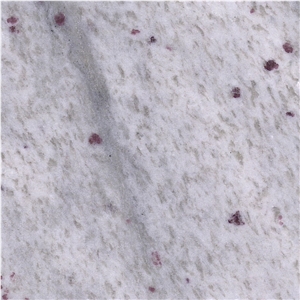

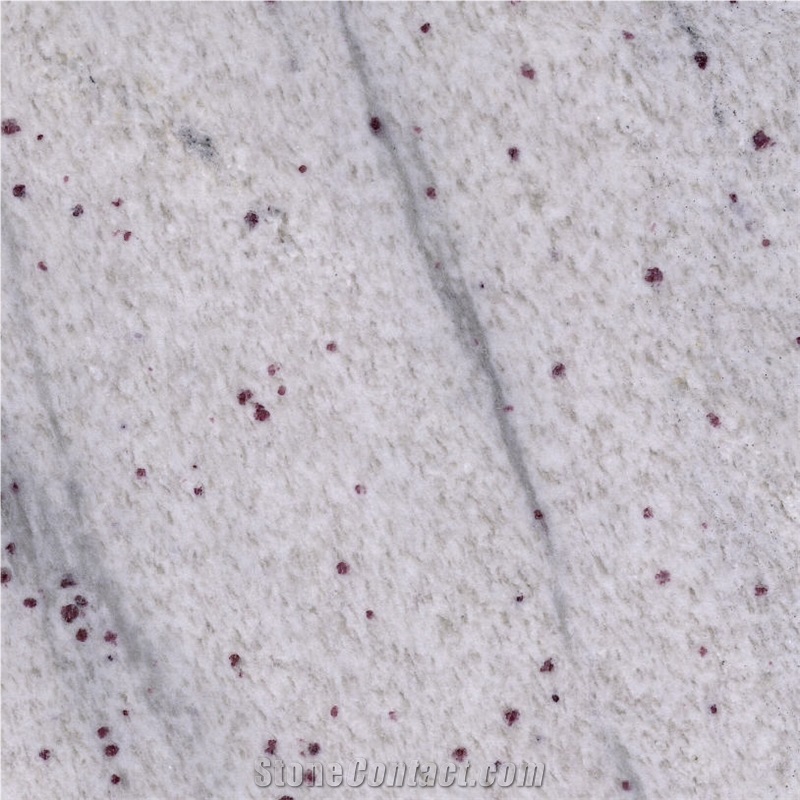

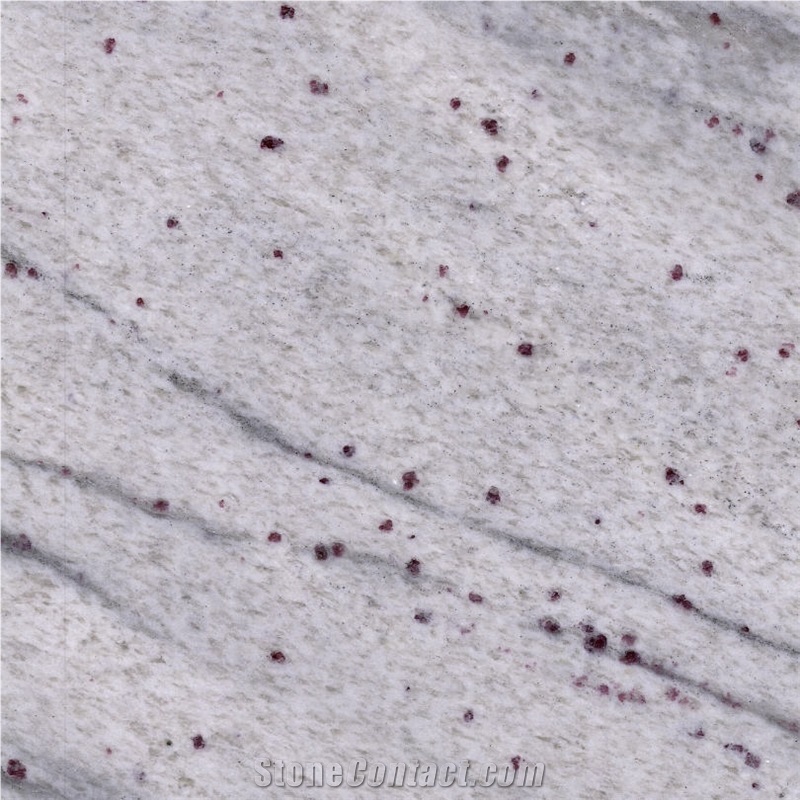

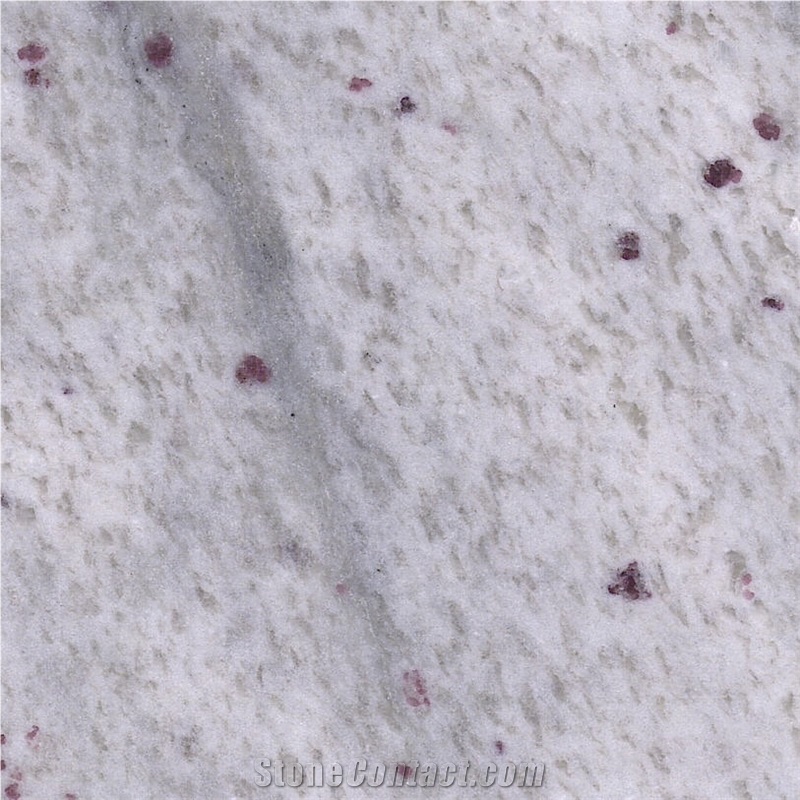

White Panther Granite

India

India

White Panther Granite is an exquisite natural stone renowned for its striking appearance. Quarried in India, this granite exhibits a distinct combination of colors and patterns that make it a unique and highly desirable choice for various design and architectural applications.

Key features of White Panther Granite:

Color Palette: The primary base color of White Panther Granite is an elegant ivory white. This soft and neutral base provides a clean and versatile canvas that can complement a wide range of interior and exterior design styles. The granite's white base is accentuated by delicate gray shades that add depth and dimension to the stone. The most eye-catching feature is the presence of reddish-brown and deep-purple mica garnet spots that punctuate the surface. These spots create a captivating and dynamic contrast against the predominantly white background, adding a touch of drama and sophistication.

Natural Patterns: The red and deep-purple mica garnet spots are arranged in a pattern that is reminiscent of the rosettes found in a panther's coat, which is how this granite gets its name. This natural pattern lends a sense of organic beauty and uniqueness to each slab, making White Panther Granite a true work of art.

Versatility: White Panther Granite is versatile and suitable for a wide range of applications, including kitchen countertops, bathroom vanities, backsplashes, flooring, and wall cladding. Whether used in contemporary or traditional settings, it brings a touch of elegance and individuality to any space.

Origin: Sourced from quarries in India, this granite is known for its quality and is associated with a region with a rich history of stone extraction.

In summary, White Panther Granite is a testament to nature's artistry. With its ivory white base, gray shades, and striking mica garnet spots pattern, it adds a sense of drama and uniqueness to any design. Whether used as a focal point or an accent, this granite creates a visual statement that is both sophisticated and visually engaging.

How thick is India's White Panther Granite slabs?

Can I use White Panther Granite in a steam room?

Is polished White Panther Granite floor slippery when wet?

How are White Panther Granite columns installed?

What is the composition of White Panther Granite?

Is India's White Panther Granite an expensive stone?

What width should a White Panther Granite hand rail be?

Can India's White Panther Granite be used exterior applications in very dusty climates?

Are polished White Panther Granite steps slippery?

How do you clean a White Panther Granite fireplace?

What is the standard angle for a White Panther Granite window sill?

Does White Panther Granite countertop scratch easily?

Does White Panther Granite countertop stain easily?

What height should a White Panther Granite balcony railing be?

What is the recommended White Panther Granite window sill slope?

Can India's White Panther Granite be used in a office?

Is White Panther Granite good for bathroom walls?

Can India's White Panther Granite be used outdoors?

Can India's White Panther Granite be used in landscaping?

How is White Panther Granite arc slab polishing done?

Is white marble or White Panther Granite better for window sills?

What are the properties of White Panther Granite?

Is White Panther Granite hard to maintain?

Is White Panther Granite good for fireplace?

How is White Panther Granite hollow column paneling polished?

What are the measurements for a White Panther Granite window sill?

Is White Panther Granite good for dinner table tops?

Are there color variations of India's White Panther Granite?

What is the coefficient of friction of Polished India's White Panther Granite tiles?

Is White Panther Granite a good choice for kitchen countertops?

How do I clean White Panther Granite window sills?

Is White Panther Granite good for high heat?

What is the thickness of a White Panther Granite table top?

What should the edge profile of a White Panther Granite window sill be?

What grade is India's White Panther Granite?

-

India

India

10YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

10YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

TINA STONE IMPORT & EXPORT CO.,LIMITED

China

China

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

China

China

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

China

China

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Goldtop ( Xiamen ) Imp. & Exp. Co., Ltd.

China

China

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Xiamen Global Stone Imp. & Exp. Co.,Ltd.

China

China

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

China

China

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

China

China

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

The request includes: 1. surface finished, size 2. quantity required

Slovenia

Slovenia