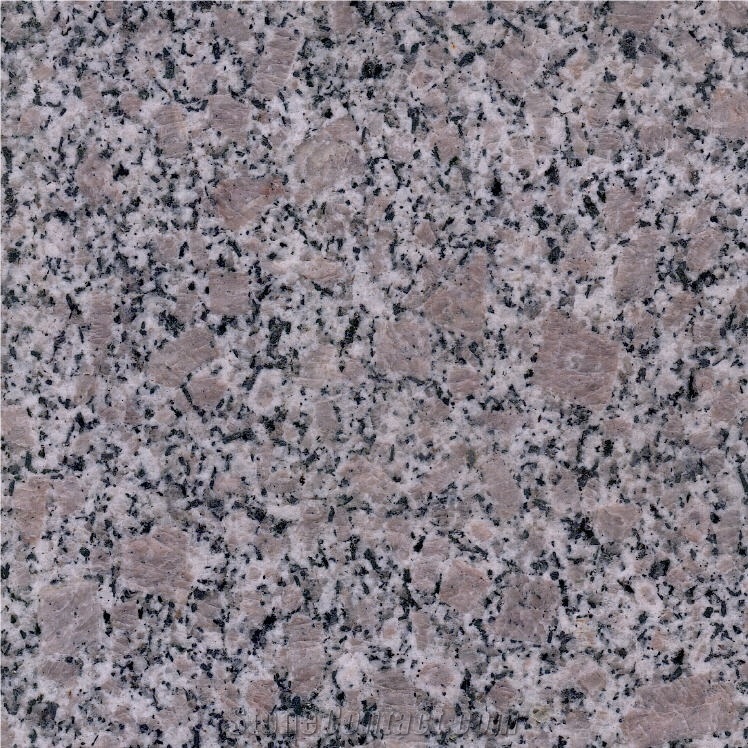

Brown Star Granite

Italy

Italy

Brown Star Granite is a kind of brown granite quarried in Italy. This stone is especially good for Exterior - Interior wall and floor applications, monuments, countertops, mosaic, fountains, pool and wall capping, stairs, window sills and other design projects. It also called Star Brown Granite, Rosa Beta Granite, Rosa Beta Gamma Granite . Brown Star Granite can be processed into Polished, Sawn Cut, Sanded, Rockfaced, Sandblasted, Tumbled, Flamed and so on.

What grade is Italy's Brown Star Granite?

What is the coefficient of friction of Water Jet Cut Italy's Brown Star Granite tiles?

How can I cut Brown Star Granite cobbles?

How many square feet does 1 ton of Brown Star Granite cobblestone cover?

What is the disadvantage of Brown Star Granite sink?

What is the difference between Brown Star Granite cobbles and pavement tiles?

What is the sand between Brown Star Granite cobblestones?

Can I cut Brown Star Granite tiles myself?

Should I do undermount sink with Brown Star Granite?

What are the common sizes of Brown Star Granite cobble stones?

Can Italy's Brown Star Granite be used exterior applications in cold climates?

Can Italy's Brown Star Granite be used outdoors?

What size is a Brown Star Granite cobblestone?

How thick is Italy's Brown Star Granite slabs?

Is it Brown Star Granite kerbstone or curbstone?

Why are cobblestones called cobblestones?

How much does a Brown Star Granite cobblestone weight?

What is the best thickness for Brown Star Granite bar countertops?

Is it better to cut Brown Star Granite wet or dry?

How much does Brown Star Granite kerbstone weight per meter?

How thick should Brown Star Granite cobblestone be for a driveway?

Is Italy's Brown Star Granite an expensive stone?

Do Brown Star Granite sinks crack easily?

How standard thick is a Brown Star Granite curbstone?

What are the common surface treatments of Brown Star Granite cobblestones?

Can Italy's Brown Star Granite be used in a office?

Is Brown Star Granite good for a bathroom vanity top?

Can Italy's Brown Star Granite be used in floor coverings?

Is Brown Star Granite cobblestone slippery when wet?

How many square meter does 1 ton of Brown Star Granite cobblestone cover?

What is the difference between Brown Star Granite cobbles and paving setts?

How can I clean between Brown Star Granite cobblestones?

Which sink is better Brown Star Granite or stainless steel for kitchen?

Are there color variations of Italy's Brown Star Granite?

What are the different types of Brown Star Granite curbs?

How much does Brown Star Granite curb weight per foot?

The weight of granite curbs can vary depending on various factors such as the size, thickness, and density of the specific type of granite being used. It would be best to check with the supplier or manufacturer of the Brown Star Granite curb for accurate information on its weight per foot.

How long does a Brown Star Granite sink last?

-

-

Brazil

Brazil

Contact Supplier

-

Xiamen Fancies Industrial Co., Ltd

China

China

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Xiamen Hibo Stone Industry Co.,Ltd

China

China

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Ukraine

Ukraine

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Contact Supplier

-

Ukraine

Ukraine

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Contact Supplier

-

Ukraine

Ukraine

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Contact Supplier

-

TINA STONE IMPORT & EXPORT CO.,LIMITED

China

China

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

5YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

Ukraine

Ukraine

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

6YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Contact Supplier

The request includes: 1. surface finished, size 2. quantity required